VEOLIA, FRANCE: Stationary crane OBX-V

Automation for stationary cranes

Cranes used for load handling must guarantee continuous operation due to the increasingly high handling volumes – and have thus become an integral part of the production process. Consequently, the increasing automation of these crane systems is a logical step.

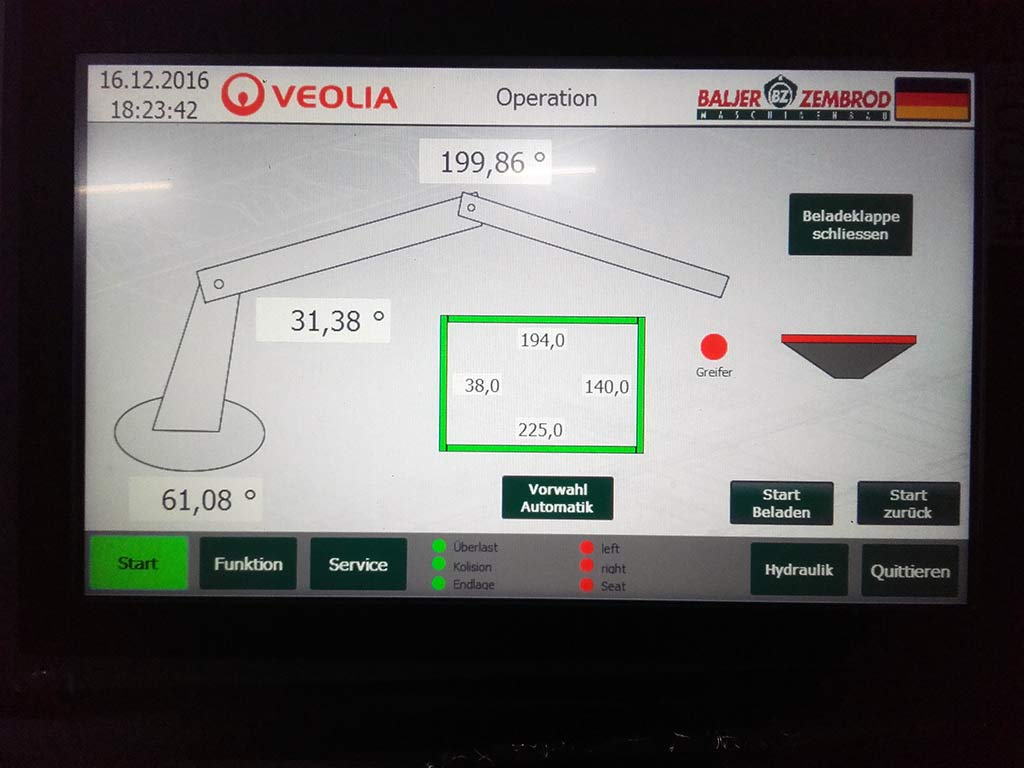

Together with the customer Veolia France in Bordeaux, Baljer & Zembrod developed and implemented a project for the automation of a stationary crane.

Veolia approached the French Office of Baljer & Zembrod, ‘BZH’, with the following requirements: in a confined space that required protection in accordance with APEX guidelines, a heavy-duty crane was needed to handle explosive industrial waste in a three-shift operation. At the same time, it was essential that the crane would not come into contact with the walls, trough or hopper at any time.

The new crane also had to allow control from an external office via a camera system.

The proposal put forward by Baljer & Zembrod involved automating the handling path around the various obstacles within this confined space. As before, the operator controls the pick-up and depositing of the material from a safe monitoring room. The type "OBX-V" stationary crane has been in operation at Veolia France since January 2017.

Work sequence:

· The material is picked up by the operator. Crane in starting position.

· At the “push of a button" the crane moves independently over the hopper.

· The material is deposited by the operator.

· At another “push of a button" the crane moves independently back over the bunker.

· The operator can control the crane manually and drive it automatically.

· During manual operation the crane can only be driven via cameras.

About Veolia Group:

Internet: www.veolia.com